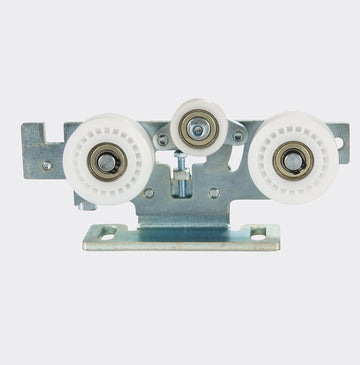

Dorma track wheels (ES200 9925518001150)

ES200 Automatic Sliding Door Carriage/Hang Wheel/Trolley/Door Connection

ES200 carriages, hang wheels, sliding door trolleys or door connections, are fixed on door panels or door wings as connections to the track rail profile, for frameless sliding glass doors or french doors, a glass clamp is required to joint the glass panel and trolleys. (This carriage is fully compatible with Dorma ES 200)

Typically, there are 4 pieces carriage in a standard pack of ES200, each moving wing of door needs 2 pcs.

● Bi-parting sliding doors or double sliding doors – 4 pcs ( left x 2pcs, right x 2pcs )

● Single sliding doors – 2 pcs ( left x 1pc, right x 1pc )

Key Specifications

Model / Part Name: ES200 / ES200e Carriage Wheel Assembly (also known as Dorma Carrier, ES200 Carriers, Carriage/Hang Wheel). OEM-style reference often listed as 9925518001150.

System Compatibility: Designed for ES 200 operator family; widely used on ES 200 “Standard,” ES 200-2D, and ES 200 EASY/ES200e variants.

Function: Precision trolley that links each sliding door leaf to the ES 200 track rail; the assembly uses two load-bearing rollers plus a smaller anti-riser (anti-jump) guide wheel and provides height/level adjustment via an eccentric wheel.

Quantity per Door: Two carriers per moving leaf (left + right). A bi-parting entrance uses four carriers total.

Operator Weight Context:

- ES 200 Standard: up to 1 x 200 kg or 2 × 160 kg.

- ES 200-2D: 1 × 150 kg or 2 × 130 kg.

- ES 200 EASY: 2 × 100 kg.

Door Types: Compatible with framed aluminum leaves or frameless glass when paired with the appropriate glass clamp between glass and trolley.

Typical Kit: Left and right carriers supplied; standard ES200 sets use 4 pcs for two-leaf doors.

FAQ

Q1. Is this “Dorma Carrier” fully compatible with ES 200 / ES 200 EASY?

A. Yes. This carrier style is built for ES 200 family rails and door connections and is commonly specified for ES 200, ES 200-2D, and ES 200 EASY installations.

Q2. How many ES200 Carriers do I need per door?

A. Use two per moving leaf (one left, one right). Bi-parting doors therefore require four carriers total.

Q3. What does the small middle wheel do?

A. That is the anti-riser guide wheel. Together with the carrier’s eccentric wheel, it lets you level the leaf and prevents uplift. After adjustment, the anti-riser should not contact the top track along the travel path.

Q4. What door weights does this support?

A. Follow the operator’s certified limits: ES 200 up to 1 x 200 kg or 2 × 160 kg; ES 200-2D 1 × 150 kg (and often 2 × 130 kg bi-parting); ES 200 EASY 2 × 100 kg.

Q5. I’m hanging frameless glass. Do I need anything else?

A. Yes—use rated glass clamps between each glass leaf and trolley to join the panel to the rail profile.

Q6. How do I level the door after hanging it on the Carriage Wheel Assembly?

A. Adjust height/level via the eccentric carrier wheel and set the anti-riser so it clears the rail at all positions. Then tighten lock-nuts.

Professional Product Overview

The ES200 Carriage Wheel Assembly often called the Dorma Carrier, which is the precision trolley responsible for suspending each door leaf on the ES 200 track and delivering smooth, quiet travel in demanding commercial environments. In every ES 200-class opening, the carriers do the heavy lifting: they bear the door load, maintain alignment with an anti-riser guide wheel, and provide millimetric height adjustment through an eccentric mechanism to fine-tune clearances and sightlines.

Compatibility you can trust. ES 200 is one of the most widely deployed automatic sliding door platforms, supported across standard, escape-route (ES 200-2D), and cost-optimized (ES 200 EASY / ES200e) variants. This carrier assembly is designed for that fitting ES 200 rails and door connections—an important advantage for facility engineers who need predictable spares and short downtime. In practice, that means straightforward hang-and-adjust service calls whether you’re replacing worn rollers in a retail storefront or re-commissioning a hospital corridor entrance after glazing work.

Performance aligned to the operator. The correct Carriage Wheel Assembly is essential for meeting the operator’s certified weight limits and duty cycle. On the ES 200 Standard, the system is validated to 200 kg for a single leaf or 2 × 160 kg for bi-parting configurations—figures that give integrators comfortable headroom for heavier shopfronts or laminated glass. The ES 200-2D escape-route variant typically specifies 1 × 150 kg and 2 × 130 kg; meanwhile, the ES 200 EASY is rated to 2 × 100 kg in a two-leaf layout. Matching carriers to the operator class keeps the rolling resistance low, reduces rail wear, and preserves stop-to-stop travel accuracy—especially important for Partial Open and Night/Bank modes where repeatable positioning is critical.

Dual-roller stability with anti-rise control. Each ES200 Carrier pairs two primary rollers with an anti-rise guide wheel. The anti-riser prevents uplift under transient loads— wind gusts or an off-center push—and it helps maintain correct correct engagement on entrances with air curtains or pressure-controlled lobbies. The eccentric on the main roller axis offers predictable, repeatable height adjustment so you can set reveals, minimize mullion clash, and achieve silent travel along the profile.

Professional fitment guidance. For single-slide openings, hang the moving leaf on two carriers (left and right). For bi-parting entrances, use four carriers total (two per leaf). On frameless installations, rated glass clamps are required to couple each glass panel to its trolley while protecting the glass edge—never fasten directly through glass without the manufacturer’s clamp system. After hanging, level the leaf with the eccentric, set anti-riser clearances so the wheel does not contact the rail anywhere along the stroke, and then torque the lock-nuts. These steps are standard across ES 200 manuals and keep the assembly quiet and low-maintenance over long service intervals.

Why specifiers and service firms choose this “Carriage Wheel Assembly.”

Ecosystem continuity. ES 200 has been the backbone of countless storefront and institutional entrances for years. Using a carrier matched to the OEM geometry protects the investment in rails, end stops, and safety peripherals while ensuring parts availability worldwide.

Compliance ready. ES 200 platforms are engineered to the European DIN 18650 and EN 16005 safety frameworks for automatic doors. A properly adjusted carrier helps the operator achieve the monitored forces and edge safeguarding those standards expect.

Serviceability. The roller-and-axle layout is field-replaceable, with clearly documented leveling and anti-riser procedures—reducing callout time and ensuring consistent results across multi-site portfolios.

Typical applications. ES 200 Carriers are specified across retail, hospitality, transport hubs, healthcare, and corporate environments where smooth sliding, low lifecycle cost, and consistent safety performance are mandatory. Combined with the operator’s program modes (e.g., Automatic, Partial Open, Exit Only, Permanent Open, Night/Bank), precision rolling gear ensures the leaf starts and stops exactly where the controller expects, supporting sensor fields and locking alignment.

Ordering identification. Many distributors list the assembly under 9925518001150 (Dorma ES200 door carrier with two rollers). When cross-referencing, compare the roller count and spacing, the anti-riser position, and the hanger base shape and slot locations.

Installation tips for a perfect glide :

- Pre-load check. Before hanging, roll each carrier by hand; any roughness indicates bearing wear—replace instead of reinstalling.

- Level first, then seal. Use the eccentric to set the reveal and head seal clearance; only then set the floor guide and bottom seals so you don’t “chase” friction later。

- Anti-riser clearance. Set it to just clear the rail across the full stroke; contact causes noise and accelerates wear.

- Glass clamp torque. On frameless doors, always follow the clamp manufacturer’s torque and gasket guidance to avoid slippage or glass edge stress.

What’s included. One Carriage Wheel Assembly (Dorma Carrier / ES200 Carrier) configured left or right as required for your opening. Most service jobs replace carriers in pairs to ensure symmetrical rolling resistance and consistent leaf leveling.